Foot injuries are common in the workplace, but the right safety footwear can help to curb many potential on-the-job hazards. Modern work shoes provide the right level of protection without the extra bulkiness of a big boot slowing you down. That means you can focus on getting the job done with less fatigue and full coverage against workplace hazards.

Most employers require the use of safety shoes for jobs that have exposure to dangers like slip hazards or heavy, falling objects. In these cases, there will likely be specific safety ratings and compliance labels required for your footwear. To learn more, click here to read our guide to ASTM, OSHA and ANSI safety footwear. Regardless of whether your employer has specific requirements, it's always a good idea to protect yourself on the job.

In this guide, we cover everything you need to know about choosing the right pair of work safety shoes. We explain each style of shoe and their uses, the different safety toe types available, the components that make up safety shoes, and important features and fit tips. If you think you may need a work boot instead, check out our guide on how to choose work boots.

Toe Types

One of the most notable features of a work safety shoe that sets it apart from an athletic or dress shoe is the addition of a safety toe. Metal or composite toe boxes provide protection from heavy, falling objects, a common occurrence in a work environment. There are other toe types to consider, too, depending on what your work entails. These are the most common safety toe types and their characteristics.

-

Steel Toe Work Shoes

The classic steel toe box provides uncompromising protection against heavy impacts. Steel toes are not without their drawbacks, though; they can become overly hot or cold depending on the outside temperature, and their added weight can result in fatigue. Still, the level of protection afforded by steel toe shoes can't be overstated. Shop Steel Toe Work Shoes -

Composite Toe Work Shoes

Composite toe caps are made of non-metallic materials like plastic, carbon fiber or kevlar, which makes them a great choice if you have to pass through a metal detector every day for your job. They're about as light as a safety toe can get, which means they're relatively comfortable (albeit not as fortified as steel). Shop Composite Toe Work Shoes -

Alloy Toe Work Shoes

Made from a mix of different types of metals, alloy toe boxes can be up to 50% lighter than steel while offering a comparable level of protection. The drawback? They tend to be pricier than their steel counterparts. Still, the reduced weight may be worth the increased cost for some workers. Shop Alloy Toe Work Shoes -

Aluminum Toe Work Shoes

Like alloy toe boxes, aluminum safety toes are lighter than steel. They're thinner than steel, too, which means they offer more room in the toe box itself. On the other hand, they cost more than steel toe shoes on average, and they're not quite as compression and impact-resistant. Shop Aluminum Toe Work Shoes -

Soft Toe Work Shoes

For the best in lightweight comfort, you can't go wrong with a soft toe work shoe, especially if your job doesn't require a safety toe. Work shoes are lighter than work boots to begin with, and the lack of a safety toe helps shed additional weight to keep you agile and on the move. Shop Soft Toe Work Shoes -

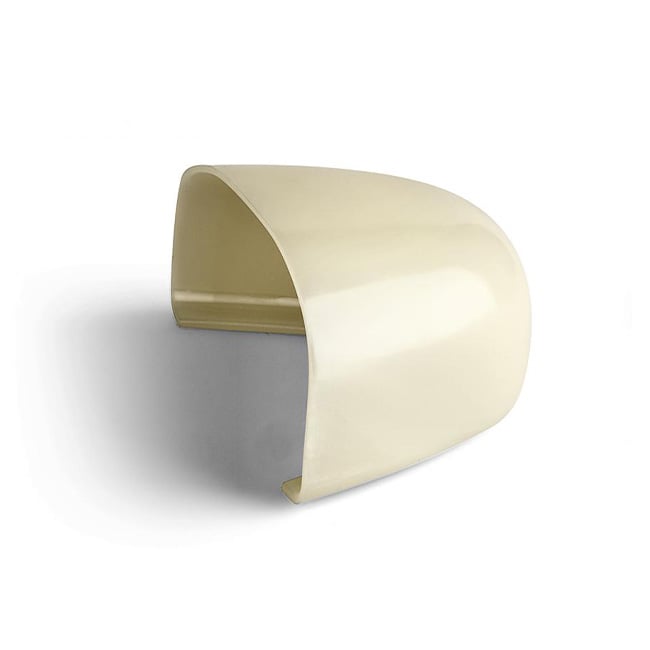

Met Guard Work Shoes

Metatarsal bones (the bones on the top of your foot) are particularly vulnerable to damage from compression and impacts. This can be rectified with a metatarsal (or met) guard: a leather or plastic flap added to the top of a work shoe for extra protection. Met guards can be internal or external, and they help prevent injuries to particularly fragile bones. Shop Met Guard Work Shoes

Work Shoes Styles

Not all work shoes are created equal; they come in a variety of styles that are suitable for all kinds of different jobs and trades. Whether you work in a warehouse or as a waiter, check out the styles below to figure out which type of work shoe works best for you.

-

Athletic Work Shoes

Athletic work shoes combine the light, comfortable features of tennis shoes with robust work features you need on the job — think mesh uppers and a comfortable cushioned midsole combined with a grippy rubber lug outsole and a protective toe box. These work shoes are great for jobs where you're on your feet all day and that allow you to dress more casually. Shop Athletic Work Shoes -

Service Work Shoes

Do you work in a kitchen? Are you a waiter or a chef? Then you need a service work shoe. Usually all-black, the main feature of service shoes is their non-slip outsole, imperative for working in environments with slippery floors. They may also come with a safety toe box, breathable uppers and a comfortable midsole to keep your feet feeling great throughout your shift. Shop Service Work Shoes -

Romeo Work Shoes

Romeo work shoes are unmistakable: they're characterized by all-leather uppers with an elastic band on either side of the ankle which makes them easy to slip on and off. Their simple, straightforward and classic design makes them a great pick for ease of use and maximum comfort. Shop Romeo Work Shoes -

Casual and Dress Work Shoes

Style and safety aren't mutually exclusive, as casual and dress work shoes demonstrate. These shoes are essentially oxfords, loafers and chelseas built with typical job site features like safety toe boxes, electrical hazard protection and non-slip soles. Casual and dress work shoes are the prime option for those who need to maintain a professional appearance in hazardous working conditions. Shop Casual and Dress Work Shoes

Work Shoes Components

All the amazing technology and safety features that go into work safety shoes wouldn't be possible without the components and materials that make them up. You can think of a work shoe as consisting of three distinct sections: the upper, which wraps around the top of your foot, the midsole, which connects the interior and exterior of the shoe, and the outsole, which makes direct contact with the ground. Each of these sections is made from important and innovative materials that work together to create a safe, functional, comfortable work shoe.

Work Shoe Uppers

Most work boot uppers are made from one or more types of leather. Work shoe uppers, on the other hand, are typically a combination of leather and a synthetic material. These synthetic materials are what make work shoes lightweight, breathable and unique from their work boot counterparts. Here are some examples of the materials from which work shoe uppers are made.

Full-grain Leather

Full-grain leather is largely considered the highest quality leather on the market. Work shoes feature full-grain leather in combination with synthetic materials to increase durability. If your shoes are made from this kind of leather, they should hold up for a while.

Nubuck Leather

The other common type of work shoe leather, nubuck leather is exceptionally waterproof. When used alongside a waterproof synthetic material like nylon, nubuck leather work shoes are a top choice for those who work in wet environments or tend to get caught in the rain on the job.

Nylon

Nylon is a silk-like thermoplastic fabric renowned for its combination of durability and flexibility. These qualities make it a great choice of work shoe material. Nylon is particularly common in athletic-style work shoes. Used in many other types of work apparel and equipment like shirts, pants, gloves and tool bags, nylon is weather-resistant, heat-resistant and very long-lasting.

Mesh

All-leather work footwear has a very noticeable drawback: the wearer's feet can't breathe and become very hot and sweaty as a result. Work shoes tend to feature mesh in their uppers as a remedy to this problem. Synthetic mesh materials are breathable, lightweight and flexible, maximizing environmental comfort while offering the very best in mobility.

Work Shoe Midsoles

With every step you take in your work shoes, your feet push down on and compress the shoes' midsoles. Because of this, it's essential for midsoles to be made from materials that can handle continuous pressure while maintaining their shape. The following are some of those materials that work to keep your feet comfortable and your shoes durable over time.

Ethylene Vinyl Acetate (EVA)

Commonly known as EVA, ethylene vinyl acetate is a foam material specifically designed to return to form after being continuously compressed. It does eventually succumb and lose its integrity, but even a flattened EVA midsole is better than no cushioning at all. Plus, an aftermarket insole can easily remedy the issue and revitalize a sturdy old pair of work shoes. Shop Work Shoes with EVA Cushioning

Polyurethane (PU)

Polyurethane, like ethylene vinyl acetate, is another foam-based material common in midsoles. It's denser and heavier than EVA, which means it tends to hold its shape better and for a longer time. This longevity comes with a price: work shoes with PU midsoles are more expensive than their EVA counterparts.

Shanks

A shank is a steel plate embedded in the midsole of a work shoe. Shanks can be invaluable, particularly on job sites with sharp hazards; they'll protect the underside of your foot from a nail or jagged piece of metal that pierces the shoe's outsole. If this kind of risk is common where you work, a shoe with a shank is a non-negotiable necessity. Shop Work Shoes with Steel Shanks

Work Shoe Outsoles

Outsoles take on most of the wear and tear a pair of shoes faces throughout its life. Each step means contact with rough, coarse surfaces and substances. As a result, outsoles need to be made from highly durable materials that keep you safe from slipping and falling. The materials and patterns below do just that, and they're what most work shoe outsoles are made from.

Rubber

The vast majority of work shoe outsoles are made from rubber. Grippy, durable and resistant to a myriad of dangerous and corrosive substances, it's hard to beat all the advantages that rubber outsoles offer.

Vibram, a particular brand of vulcanized rubber, is designed specifically to be used for footwear outsoles. It was invented In Italy by Vitale Baramani in 1935 and has been popular ever since. Vibram offers the top-level traction, durability and comfort you need on the job. Shop Rubber-soled Work Shoes Shop Work Shoes with Vibram Outsoles

Polyurethane (PU)

While polyurethane is used most often in midsoles, it's not uncommon to find work shoes with PU outsoles. Like rubber, it's wear-resistant and waterproof, as well as slip-resistant and grippy. Its compressibility provides an additional level of comfort for your feet throughout the day.

Tread Patterns

While not necessarily a material, tread patterns are an important component of work shoe outsoles. A tread's pattern can determine how a shoe handles different surfaces; deeper tread patterns are better suited for rough, uneven ground. Plus, work shoes with deep treads are easier to clean and maintain. Be sure to pay attention to the tread pattern of the shoes you're planning to purchase to get the best use out of them.

Work Shoe Features

After you've decided on the toe type, style and appropriate components, the next thing to consider when shopping for work shoes is the features they offer. These features offer anything and everything from additional comfort to vital safety mechanisms your workplace may require. The following features are commonly available in many different types and styles of work shoes.

Electrical Hazard (EH) Protection

Electrically energized conductors and live circuits are no joke; improper safety procedures and/or use of equipment can result in serious injury and even death. Luckily, electrical hazard safe work shoes can provide high-voltage protection to keep you safe while you work. This work shoe safety feature is a no-brainer for electricians. Shop Electrical Hazard Safe Work Shoes

Water Resistance

Water-resistant work shoes are not quite the same as waterproof work shoes, but they can provide adequate protection in certain situations. By using either a coating or the natural properties of their materials, water-resistant shoes repel water, preventing its absorption. Be warned, though: if you fully submerge your water-resistant shoes, your feet won't come out completely dry. Water-resistant coatings have a tendency to lose their efficacy over time, too, but coatings can be reapplied as needed. Shop Water-resistant Work Shoes

Waterproof

Waterproof work shoes, on the other hand, are better at keeping water out altogether. When shoes are constructed from water impermeable materials, the protection is sureproof. However, there is the added drawback that any sweat that builds up inside the shoe cannot escape. To get around this problem, many work shoes are made with GORE-TEX in their construction, a waterproof, breathable fabric membrane. This membrane repels water in liquid form, but allows water vapor inside the shoe to pass through it. Shop Waterproof Work Shoes

Non-metallic

Many jobs require employees to pass through a metal detector every day before their shift. If you require a safety toe, a steel or alloy toe box may cause you to have to take your shoes off and put them back on multiple times a day. Non-metallic work shoes remedy this problem by replacing metal safety features (like toe boxes and shanks) with composite alternatives. Shop Non-metallic Work Shoes

Puncture Resistance

Anyone who's stepped on a nail before can tell you it's not fun. If there are nails, broken glass, metal scraps or any other puncture hazards on the ground frequently at your place of work, you may want to consider wearing puncture-resistant work shoes. They come with a steel or plastic shank built right into the footbed to protect your feet from any hazards that may poke through. Shop Puncture-resistant Work Shoes

Oil Resistance

Oil is common in many industrial work sites. It's also harmful and corrosive: it can ruin your shoes over time, and you definitely don't want it seeping through your footwear and onto your skin. Oil-resistant work shoes are designed to stand up to abrasion from oil, resulting in more durable work shoes in the long run. They also work to keep oil out of the shoes and away from your bare feet. If you work with or around oil on your job site, this feature is a must. Shop Oil-resistant Work Shoes

Chemical Resistance

Hazardous chemicals can be unpredictable and extremely dangerous. They can irritate your skin and eyes, and they can cause anything from an all-day annoyance to a debilitating injury. If you work with these types of materials, you certainly need chemical-resistant footwear. Be sure to work with your employer to ensure the shoes you buy cover the chemicals with which you work. Shop Chemical-resistant Work Shoes

Slip Resistance

According to the CDC, 27% of all nonfatal workplace accidents in recent years are due to slips, trips and falls. Many of these injuries are easily preventable with the right kind of footwear. If you work in an environment with frequently wet floors or smooth, tractionless surfaces, slip-resistant footwear can go a long way to keeping you on your feet. Shop Slip-resistant Work Shoes

Heat Resistance

Industrial occupations carry with them a wide range of hazards, one of which is extreme temperatures. If you're a welder, a construction worker, a roofer or a foundry worker, heat-resistant shoes are a must-have. They can both handle the extreme temperatures while maintaining their integrity and insulate your feet to keep them safe. Shop Heat-resistant Work Shoes

Work Shoe Fit Tips

Be sure to prioritize fit when choosing your next pair of work shoes. Finding the right features and price is important, but ultimately you need to be able to wear these shoes comfortably day in and day out. The following tips should help to ensure you don't have any issues.

Usa A Brannock Device

Have you ever been into a shoe store and seen those oblong, adjustable devices into which you put your foot in to find your size? That's called a Brannock device, and they can help to ensure your shoes fit well. Having measured your size can be especially helpful when buying online, so be sure to measure before you click.

Stick with the Same Brand

One of the biggest issues shoppers have is sizing inconsistencies between brands. What one company calls a 10 may be a 10.5 or even an 11 to another. On the other side of this coin, though, is that one brand's sizing should be consistent within itself among its many pairs of footwear, so if you find a brand you like, stick with it when you can.

Socks

When you're trying your shoes on for the first time, you should try them on with the same style and/or type of socks you plan to wear with them regularly. This will help to ensure a consistent fit and avoid any discomfort down the road. Shop Work Socks

Try Aftermarket Insoles

The right orthotic can make all the difference. A new insole can provide some more space in a tight-fitting shoe, or tighten up an overly loose shoe. Plus, it doesn't hurt that aftermarket insoles tend to be more comfortable than the ones that come with your shoes. Shop Insoles

Adjust Your Laces

You'd be amazed how a simple lace adjustment can make all the difference both in comfort and performance. You want your laces to be tight enough so that your shoes don't rattle around, but not so tight that they're cutting off circulation to your feet or toes.

No Heel Movement

A loose pair of shoes is a great way to wind up with blisters. If your shoes are sliding around as you walk or work, the back of the shoe can rub against your heel, causing terrible irritation. If your heel can move around in your shoes, you probably need a smaller or narrower style.

Toe Room

In a similar way, you don't want your toes to be too tight in the toe box of your shoes. When you try your shoes on before buying them, try to curl your toes. If you can, then they probably fit the way you need them to. If you can't, try going a half size up.

Safety Toes Take up Space

It's important to remember this. After all, the safety toe box is essentially a hunk of metal or plastic that has to fit into the shoe, and in turn, your toes have to fit inside it. You may need to go up a half size or more to ensure your toes fit properly into a safety toe box.

Snug, but Never Uncomfortable

Snug does not mean tight; it means constrictive enough to prevent sliding and blisters, but not so constrictive as to feel painful. If your shoes are loose and causing irritation, you need to size down. If they're so tight they're hurting you, size up.

Give Your Shoes Time to Break In

Sometimes (especially for shoes that seem a little tight), the best thing to do is just give your shoes a little time to loosen up. Leather in particular is a pretty rigid, durable material, but if you walk around enough in your new shoes, they'll loosen up a bit and feel more comfortable in time.

Like any other piece of on-the-job equipment you use day in and day out, work shoes are an important purchase that you shouldn't take lightly. Do your research. Figure out which style would work best for your job. Consider the features you'll need. Find out which safety toe option is appropriate for you. If you put in the right amount of time and scrutiny, you'll wind up with a great pair of work shoes that you can wear for years to come.

Did you find this article helpful?